After many software based distortion variations on Basscape I thought I would go more old-school. Most overdrive circuits are too gentle and most distortion circuits are too fierce in my very limited experience forcing me to make a decision as to which one do I want. Decisions were never my strong suit so I chanced upon an interesting schematic from an Orange Crush 15R.

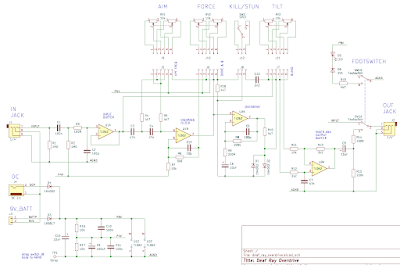

The overdrive in this schematic is shown at the top centre. By varying the drive control it doesn't just change the gain before a pair of clipping diodes that either shunt the signal to ground or use it as feedback, it blends between them. With the drive at max it is full-on hard shunt clipping, with the drive at minimum it is a barely perceptible feedback soft clipping with the ability to dial in anything in-between. Brilliant!

To give it a different feel to the original, the signal is passed through a 2-pole highpass filter that can be varied from around 200Hz to 650Hz. In addition to the frequency adjustment, the Q of the filter (the peakiness of the response) is controlled in tandem with the drive control described above. At low drives the filter is fairly relaxed removing the low end that can otherwise dominate the overdrive tone. As the drive is increased, the filter Q rises and the tonal character can become more exciting and distinctive.

The range of Q goes from about 0.7 (vanilla) to around 2.3 (mint choc chip). As with the high-pass frequency range this was mostly determined by trying it out until the the best range was found for the controls. The economical-on-battery-juice-and-my-pocket TL062 was used and all pots were chosen to be the same value so I only had to buy one lot.

As I tend to play bass much more than a six-string I wanted a blend control more than an output level. The blend mixes the overdiven signal with a slightly filtered dry signal to still provide the bass guitar underpinnings even if theres a good helping of edginess going on. Which there usually is...

To avoid a complete rats nest of wires I mounted the pots on a separate piece of veroboard. The whole lot was fitted into a 1590BB diecast box and some artwork made to confuse onlookers. The Deaf Ray theme came about as I liked the idea of a laser on the front and in turn this caused the sensible controls like 'frequency' and 'drive' to be renamed to 'aim' and 'force'. The 'kill/stun' switch gives a more cutting sound with higher drive (kill) or a gentler warmer tone (stun).

The artwork was printed onto A4 coloured adhesive paper and lined up with the drilled holes before covering with a transparent adhesive film layer to protect it. Much better looking than my usual permanent marker pen scrawl.

All the parts managed to squeeze into the box along with the two 1/4" jacks, dc supply, footswitch and controls.

I was so pleased I made two...

Aim. Fire!